![]() As a leading electronic product design and development company, Cardinal Peak helps brands bring new electronic innovations to market quickly by utilizing our proven product engineering process. With skills in electronic hardware development, mechanical design and embedded applications, our team of engineering experts does it all — from cost-sensitive, high-volume products to highly advanced standalone instruments.

As a leading electronic product design and development company, Cardinal Peak helps brands bring new electronic innovations to market quickly by utilizing our proven product engineering process. With skills in electronic hardware development, mechanical design and embedded applications, our team of engineering experts does it all — from cost-sensitive, high-volume products to highly advanced standalone instruments.

Electronic Product Design and Development Process

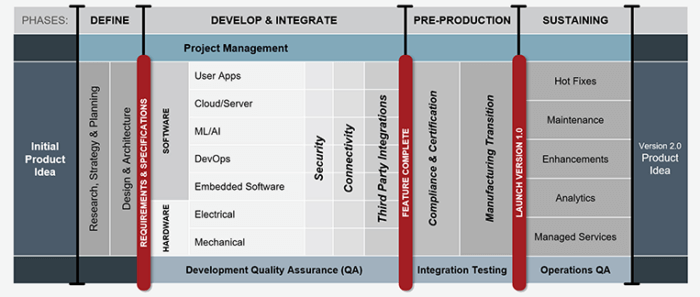

Throughout every phase of electronic product development, we assemble the right team of engineers to tackle the activities required to design your electronic device. During the definition stage, we clarify requirements, estimate development and operational costs, and create a high-level architecture. We may de-risk certain portions of the electronic product development by creating proof-of-concept models as needed. The “define” stage concludes when we deliver a complete statement of work (SoW) with budget and schedule. For more information about how the materials developed in the define stage can be used to validate your business model, check out our “From ROM through SoW: The Importance of Communication During Product Development” blog post.

Electronic Hardware Design & Development

During the “develop and integrate” phase, the electronics and housings are created. This includes the industrial design (the look and feel of the mechanical package) and the subsequent detailed mechanical design. This phase also includes schematic capture, PCB layout, and board bring-up. One of the most common challenges for the electronic hardware development team is optimizing the bill of materials (BOM) since the product needs to meet price expectations at the anticipated volume. We balance the BOM cost with the NRE costs to address your business needs. Other common challenges we see regularly include:

- Optimizing the BOM for supply chain availability

- Battery power optimization

- Radio(s) integration and FCC certification

- Environmental testing (shock, vibration, temperature, etc.)

Embedded Software Development, QA & Compliance

In parallel to mechanical and electronic hardware development, our engineers develop embedded software that controls your device. We initially build on dev kits then switch to the target hardware after board bring-up. Features are developed on a sprint-by-sprint basis, and as each new feature is added, our QA team is testing as described in this blog post highlighting our project execution process. Once all features are developed and integrations are done, testing expands to include alpha (friends and family) and then beta tests which our software QA can manage for you.

Product Manufacturing Transition

Once the product is developed, integrations are implemented, and compliance certifications are received, our electrical and embedded engineers will transition the design to your selected contract manufacturer. If you don’t have a preferred contract manufacturer, we can help to find the right one given your expected volume and the technology mix. The manufacturing transition phase often involves developing custom test and calibration fixtures or procedures to be used in production.

As you can see, typical electronic product design requires a multifaceted team of engineers working in concert to release a product to commercial production. While many firms providing electronic product development services can build a prototype, achieving the quality necessary for commercial release demands a talented team using a proven process. Leverage Cardinal Peak’s electronic product design and development expertise to lower your risk.

Our Electronic Product Design Case Studies

As a top electronic product design company, Cardinal Peak supports innovative electronic product designs, including the projects below. Contact us today if you’re looking for a partner to help with engineering electronic devices.

Our Electronic Product Designs

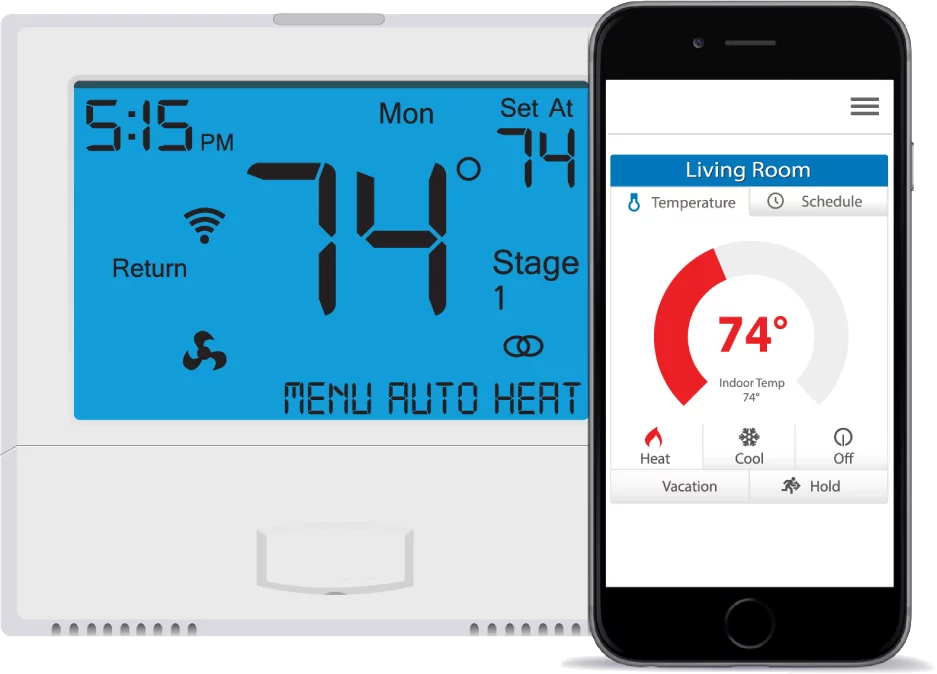

At Cardinal Peak, our diverse team of electronic product design engineers has helped organizations with electronic product development for almost two decades. This case study shares seven of our connected IoT and smart home product designs, the challenges we overcame and FAQs to help you chart your product’s development.

Engineering a True Wireless Earbud System

Designing a Portable Recording Studio

As a talented musician himself, iZotope’s CEO saw a need for a portable professional recording system where technology didn’t get in the way of a creative moment. Enter Spire Studio. Our electronic product design and development team helped iZotope create an all-in-one recording system that maximizes functionality and performance.

At Cardinal Peak, our diverse team of electronic product design engineers has helped organizations with electronic product development for almost two decades. This case study shares seven of our connected IoT and smart home product designs, the challenges we overcame and FAQs to help you chart your product’s development.

As a talented musician himself, iZotope’s CEO saw a need for a portable professional recording system where technology didn’t get in the way of a creative moment. Enter Spire Studio. Our electronic product design and development team helped iZotope create an all-in-one recording system that maximizes functionality and performance.

Electronic Product Design and Development FAQs

As one of the top electronic product design companies, we are frequently asked the following questions about our electronic product development services.

What Are Electronic Product Design Services?

Electronic product design services include electronic hardware development, mechanical design and embedded software engineering. From architecture to development, integration and pre-production, common elements include schematic capture, printed circuit board (PCB) layout and board bring-up, developing custom antennas and ensuring compliance for certifications like FCC, UL and CE.

Beyond the electronics design elements, our engineering team also optimizes your bill of materials (BOM) and makes sure it meets cost targets while avoiding any supply chain issues. We manage the complete box-build before transitioning the volume production to your contract manufacturer.

Some common challenges found with electronics product design services include:

- Optimizing the bill of materials (BOM) for cost and supply chain availability

- Developing custom antennas and integrating radio(s)

- Optimizing battery power

- Ensuring compliance and getting FCC certification

- Selecting a contract manufacturer that fits your product’s technology mix and anticipated volume

- Automating testing and calibration

- Transitioning to a contract manufacturer

What Are the Steps of Electronic Product Design?

As a leading provider of electronic product design services, we have developed a proven process for bringing electronic innovations to market quickly. The steps in our electronic product development process include:

- Conceptualization: To research and strategize market opportunities and plan for new products.

- Definition: To describe the scope and nature of the product’s specific requirements.

- Design: To create designs, concepts and architectures for new products.

- Development: To build out the electronics, the hardware and the embedded software elements.

- Integration: To incorporate security, connectivity and third-party integrations.

- Optimization: To improve the look, performance, functionality, robustness and safety of the product by implementing feedback.

- Revise: To make any necessary revisions to the product.

- Launch: To commercially release the electronic product to market.

- Support: To enable the ongoing use or operation of the device.

How Do You Design Electronic Hardware?

Much like the process for electronic product design, hardware design involves multiple stages.

- First, you need an idea.

- Next, you need to define your concept, including key components and how they might fit together.

- From there, you need to capture schematics and refine your problem space down to an actionable manner for fixing the problem.

- Then, you might consider trying out your idea without actually manufacturing a circuit board or chip via simulation.

- The next step involves designing the printed circuit boards (PCBs) and connecting the disparate schematics and critical components.

In the world of electronic hardware design, idea definition, schematic capture, PCB layout and simulation are the all-important major stages of the hardware design process.

What is an Electronic Product Design Engineer?

A position whose skills and expertise are in demand at organizations across industries, electronic product design engineers combine creativity and engineering to design, develop, test and build electronic products. Whether planning and developing apps and modifications to improve technical performance; inspecting electronic systems, instruments and equipment to ensure safety; designing and testing the electronic equipment and components; or conceiving fresh ways to use electrical power to improve or develop products, electronic design engineers are responsible for a variety of duties. As such, electronic product design engineers should have strong technical skills in microelectronics, FPGA, electronic boards, power electronics and more.

Electronic Product Design and Development Articles

Our Product Development Process: Project Execution

Electronic product design can be difficult. To simplify the process of selecting an electronic product development partner to develop your product, this blog post highlights the importance of partnership, focusing on the success of our agile reporting and quality assurance processes.

From ROM through SoW: The Importance of Communication During Product Development

This informative blog post guides readers through the earliest stages of our electronic product development process, highlighting the critical importance of communication from the initial call through to the development of a statement of work.

Improving Design with Development Printed Circuit Boards

When electrical engineers are forced to shrink the PCB to fit within a predefined package, electronic product development challenges are created. Discover how development printed circuit boards can help with electronic product design.

Electronic product design can be difficult. To simplify the process of selecting an electronic product development partner to develop your product, this blog post highlights the importance of partnership, focusing on the success of our agile reporting and quality assurance processes.

This informative blog post guides readers through the earliest stages of our electronic product development process, highlighting the critical importance of communication from the initial call through to the development of a statement of work.

When electrical engineers are forced to shrink the PCB to fit within a predefined package, electronic product development challenges are created. Discover how development printed circuit boards can help with electronic product design.