A top-tier automotive parts supplier (over $30B in revenue) faced a critical quality control challenge. Inspecting their complex, high-precision components for subtle surface defects was a bottleneck. The parts’ reflective surfaces and varying factory lighting conditions made traditional automated inspection a probabilistic failure, forcing a reliance on slower manual checks.

A top-tier automotive parts supplier (over $30B in revenue) faced a critical quality control challenge. Inspecting their complex, high-precision components for subtle surface defects was a bottleneck. The parts’ reflective surfaces and varying factory lighting conditions made traditional automated inspection a probabilistic failure, forcing a reliance on slower manual checks.

They partnered with Cardinal Peak/FPT for Custom AI Visual Inspection Engineering. We moved beyond traditional rule-based vision, deploying a deep learning-based vision system trained to recognize anomalies on difficult surfaces. The resulting automated solution integrated directly into the production line, achieving 98%+ detection accuracy for critical defects and reducing overall inspection time by 30%.

The Challenge: The Limits of Traditional Vision on Reflective Surfaces

The client manufactures high-precision automotive components where surface integrity is critical. The primary engineering challenge was the nature of the parts themselves: they possessed complex geometries and highly reflective surfaces.

Standard “rule-based” machine vision systems struggled in this environment. Varying lighting conditions across the production line created glares and shadows on the reflective parts that traditional cameras misinterpreted as defects. Consequently, the system could not reliably distinguish between benign surface variations and actual critical defects like scratches, dents, or discoloration. This unreliability forced the client to depend on manual inspection, which was slower and subject to human fatigue.

Standard vision systems fail on reflective surfaces because they can’t distinguish between a lighting glare and a physical scratch. We didn’t just add a camera; we engineered the optical environment and trained deep learning models to understand the ‘texture’ of a defect regardless of surface reflections.

The Engineering Solution: A Deep Learning-Based Vision System

We engineered an end-to-end automated surface defect detection solution designed specifically to handle the challenges of reflective industrial parts.

Advanced Imaging & Optical Engineering

Success in visual inspection starts with the image. We designed a custom imaging setup, selecting high-resolution industrial cameras and engineering specialized illumination techniques to minimize surface glare and highlight topographic anomalies on the reflective parts.

Deep Learning for Robust Defect Detection

Unlike brittle rule-based systems, we utilized a deep learning-based vision system. We trained convolutional neural networks (CNNs) on datasets of both good and defective parts under various lighting conditions. This allowed the AI to learn the contextual “texture” of a true defect—such as a scratch or dent—identifying it accurately even when lighting varied, a capability traditional vision lacks.

Production Line Integration

The solution was not just a model in a lab; it was a fully engineered system integrated directly into the client’s high-speed production flow. The system captures images in real-time, performs inference locally on industrial compute hardware, and sends immediate pass/fail signals to the line PLC for automated sorting.

Automated Visual Inspection Pipeline Architecture

The Results: Zero Escapes, Faster Throughput

The transition to a custom deep learning-based inspection system transformed quality control for these critical parts.

- 98%+ Detection Accuracy: The system achieves extremely high accuracy for critical defects, even on challenging reflective surfaces.

- Zero Escape Rate: The robust nature of the deep learning model ensured a zero escape rate for critical defects reaching the end customer, as validated through the client’s existing quality metrics.

- 30% Reduction in Inspection Time: Automating the process significantly sped up throughput compared to previous manual methods.

Core AI

- Deep Learning (CNNs)

- Computer Vision

- Automated Surface Defect Detection

Platform

- FPT Intelligent Inspection Accelerator (utilizing technology partnerships like Landing AI)

Hardware

- High-resolution Industrial Cameras

- Custom Illumination

- Industrial PC (IPC) for Edge Inference

Integration

- PLC interface for real-time production line control

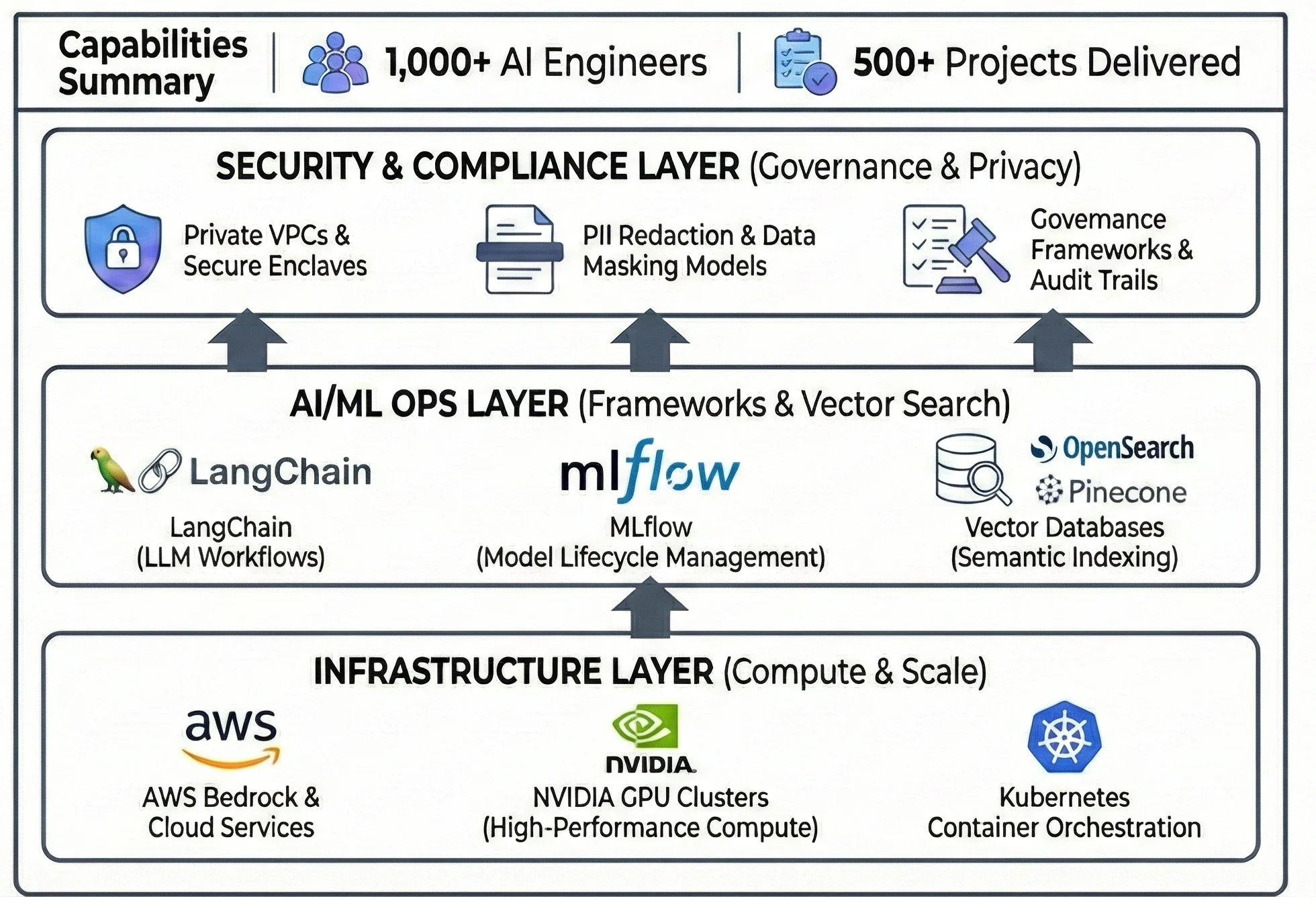

The Engine Behind the Solution

This project was executed by utilizing our expertise in Computer Vision, Deep Learning, and Hardware Integration. We leverage our advanced Intelligent Inspection Accelerator, which incorporates leading-edge technologies from partners like Landing AI, to rapidly develop robust deep learning models for complex surface anomalies. Our ability to deliver complete, turnkey inspection systems—from optical design to AI model training—makes us the ideal partner for challenging industrial quality control applications.

Our AI Center of Excellence Capabilities

Explore Engineering Services Related to Automated Inspection

Edge AI & Computer Vision Services

Learn how we deploy sophisticated AI models on industrial gateways and edge devices for real-time decision-making.

Custom AI Algorithms Accelerator

Discover our frameworks for building and tuning custom deep learning models for unique inspection challenges.

Custom AI Visual Inspection Engineering FAQs

Why use deep learning instead of standard machine vision for inspecting reflective parts?

Standard machine vision relies on rigid rules (e.g., contrast thresholds) that fail when lighting glares off reflective surfaces. Deep learning-based machine vision systems learn the visual characteristics of defects from examples. This allows them to robustly distinguish between a true scratch or dent and a harmless lighting reflection, even as conditions vary.

What is "Custom AI Visual Inspection Engineering"?

It is the process of designing a bespoke quality control system when off-the-shelf smart cameras fail. It involves engineering the entire pipeline: selecting the right optics and lighting, training custom deep learning models on your specific parts data, and integrating the software and hardware directly into your manufacturing line.

What types of defects can this system detect on high-precision components?

The deep learning models can be trained to detect a wide variety of surface anomalies. In this specific automotive application, the system successfully detected scratches, dents, and discoloration on complex, high-precision parts.

How does automated surface defect detection improve over manual inspection?

Manual inspection is slow, expensive, and prone to human fatigue, leading to inconsistent results. An automated AI system provides consistent, objective, non-fatigable inspection 24/7, significantly increasing throughput (by 30% in this case) while maintaining ultra-high accuracy (98%+).

Is deep learning suitable for high-precision manufacturing environments?

Yes. While early AI was prone to error, modern deep learning-based vision systems are specifically designed for complex, high-precision component inspection. They provide the robustness required to achieve near-zero escape rates in demanding automotive and electronics manufacturing environments.