A global manufacturer of household appliances faced a critical quality control challenge on their assembly line: human inspectors could not reliably detect subtle defects in motors and fans due to subjective judgment and intense background factory noise. To ensure consistent quality as production scaled, they needed to automate this difficult manual process with intelligent technology.

A global manufacturer of household appliances faced a critical quality control challenge on their assembly line: human inspectors could not reliably detect subtle defects in motors and fans due to subjective judgment and intense background factory noise. To ensure consistent quality as production scaled, they needed to automate this difficult manual process with intelligent technology.

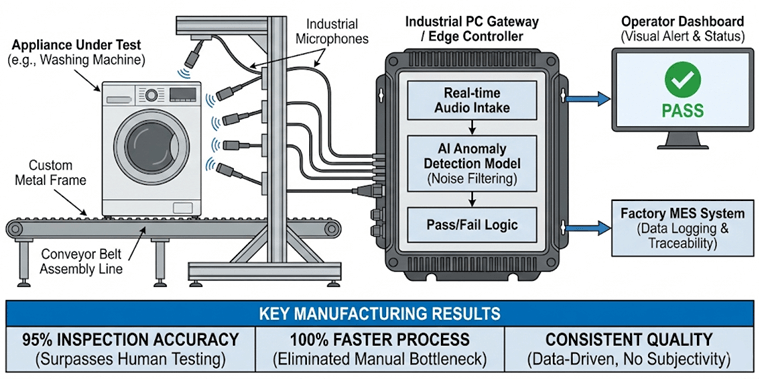

They engaged Cardinal Peak/FPT for Custom AI Test Equipment Engineering. Leveraging advanced technology for AI-powered acoustic quality inspection systems, we designed and integrated a complete, turnkey test fixture capable of “listening” to products on the line, filtering out industrial noise, and identifying defects with repeatable accuracy. The resulting system doubled inspection throughput (a 100% increase in speed) and achieved 95% accuracy within the first month of deployment.

The Challenge: The Limits of Human Inspection on the Line

The client’s manufacturing process relied on operators at the end of the assembly line to manually listen to appliances to catch defects in moving components like motors, pumps, and fans. This approach was unsustainable for scaling production, due to:

- Acoustic Chaos: High ambient noise levels in the factory frequently masked the subtle audio signatures of developing faults.

- Subjectivity & Fatigue: Inspection quality varied wildly based on the operator’s experience and fatigue levels during a shift.

- Production Bottleneck: Manual inspection was slow, creating a bottleneck that could not keep pace with increasing throughput-targets.

The client needed an engineered solution, a robust, automated test fixture that could provide objective, repeatable pass/fail results in real-time without slowing down the line.

The challenge wasn’t just ‘listening’ to the motor; it was engineering a system capable of isolating a specific frequency signature amidst the 90dB+ chaos of an active production line. We delivered an objective, automated ‘ear’ that doesn’t get tired.

The Engineering Solution: A Custom AI-Powered Test Fixture

We delivered an end-to-end Automated Test Equipment (ATE) solution, taking ownership from initial concept to a production-ready fixture integrated into the manufacturing line.

Hardware Integration & Data Acquisition

We engineered the physical test fixture to integrate seamlessly with the existing conveyor system. Our team selected and strategically positioned high-fidelity, ruggedized industrial microphones capable of capturing specific frequency bands while minimizing ambient environmental noise.

AI Model Training & Noise Cancellation

Leveraging proven industrial acoustic AI IP, our engineers trained deep learning models to differentiate between normal operating sounds and specific defect signatures. A critical part of the engineering effort was developing robust Digital Signal Processing (DSP) and noise-cancellation algorithms that allow the system to maintain high accuracy even when surrounded by other operating machinery.

Industrial Software & MES Integration

We developed the PC-based edge control software that powers the test station. This software processes real-time audio streams from multiple microphones and runs the AI inference locally on an industrial gateway, providing immediate visual feedback to operators via a custom dashboard. Crucially, we engineered the system to integrate directly with the client’s existing Manufacturing Execution System (MES) via standard industrial protocols. This ensures automated data logging and 100% traceability for every serial number, which is essential for regulatory compliance and long-term quality analysis.

Custom AI-Powered Acoustic Test Fixture (Factory Floor)

The Results: Faster, More Accurate Quality Control

The custom ATE solution transformed the client’s quality assurance process, delivering measurable operational improvements that met rigorous ROI requirements.

- 95% Inspection Accuracy: Within one month of deployment, the AI model achieved a 95% accuracy rate in detecting defects, significantly surpassing previous human benchmarks in the noisy environment.

- 100% Faster Process: Automated testing removed the manual bottleneck, doubling the speed of the inspection station to match line throughput.

- Eliminated Subjectivity: The system provides consistent, data-driven pass/fail results, removing human error and variability from the quality equation.

Hardware

- Industrial microphones

- Industrial PC (IPC) / Edge Gateway for local inference

Core AI

- Deep Learning

- Acoustic Anomaly Detection

- Noise Cancellation DSP

Platform

- FPT AI Center I2 (Intelligent Inspection) Solution

- SoundAI module

Integration

- Custom MES integration for traceability

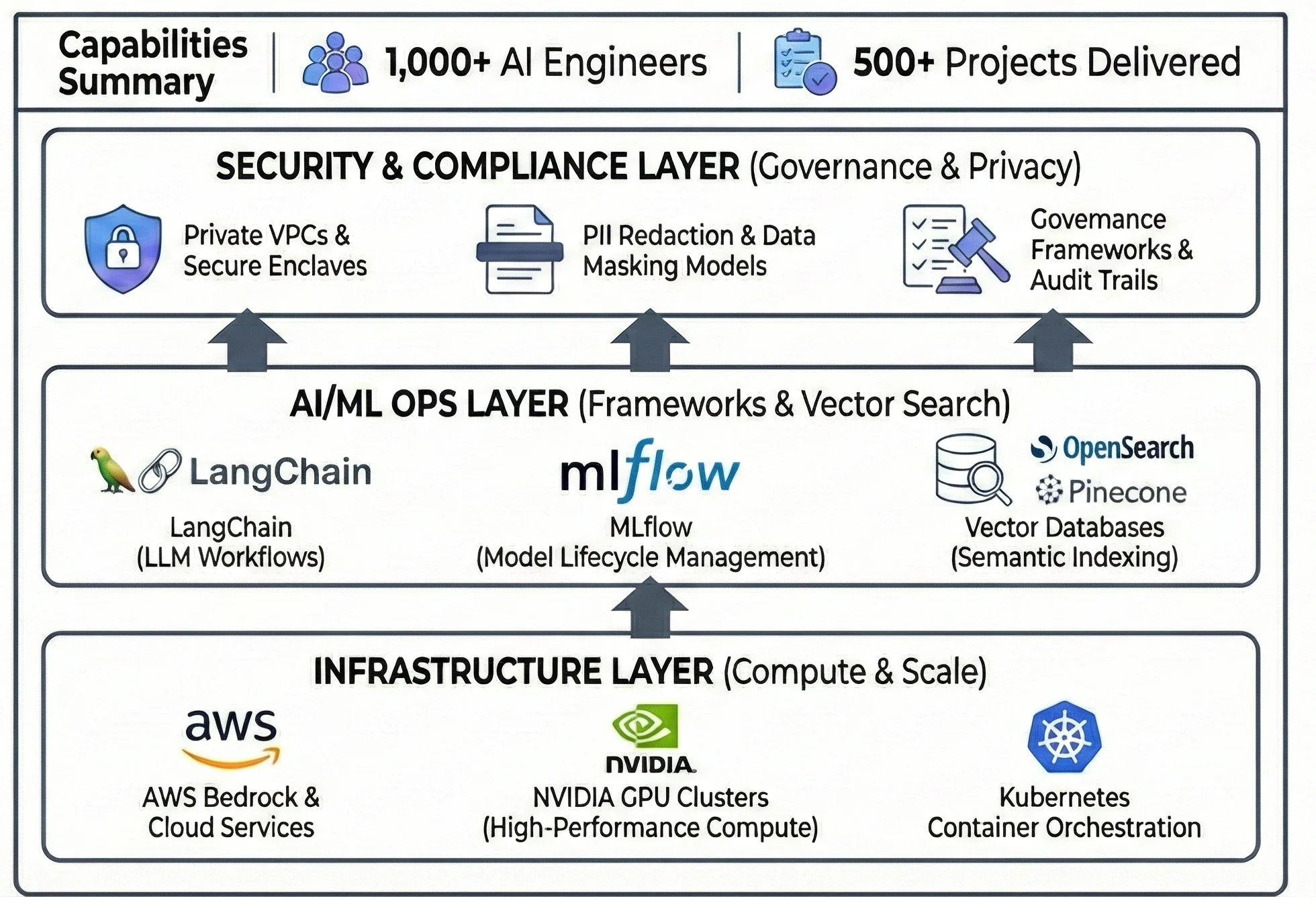

The Engine Behind the Solution

This project was executed by utilizing our expertise in Hardware Engineering, Edge AI, and Software Development. Our ability to deliver complete, integrated systems—hardware, software, and AI—makes us the ideal partner for complex manufacturing test challenges.

Our AI Center of Excellence Capabilities

Explore Engineering Services Related to Industrial AI

Edge AI & Computer Vision Services

Learn how we deploy sophisticated AI models on industrial gateways and edge devices for real-time decision-making.

Custom AI Algorithms Accelerator

Discover our frameworks for building and tuning custom deep learning models for unique inspection challenges.

AI Test Equipment Engineering Frequently Asked Questions

Why should we choose a custom AI test equipment engineering approach over off-the-shelf acoustic products?

Off-the-shelf acoustic products often struggle with the unique noise profiles and physical constraints of specific manufacturing lines. A custom engineering approach ensures the hardware fixture, sensor placement, noise cancellation algorithms, and MES integration are tailored exactly to your product and environment, resulting in higher accuracy and seamless workflow integration.

How does acoustic AI handle high levels of background noise on a factory floor?

We utilize advanced Digital Signal Processing (DSP) and noise reduction techniques before the audio even reaches the AI model. Furthermore, during the training phase, we train the deep learning models on data augmented with actual factory background noise, teaching the AI to ignore environmental sounds and focus only on the signal signature of the product being tested.

What computing hardware is required to run this type of system?

Unlike embedded product applications, factory floor systems typically use robust Industrial PCs (IPCs) or powerful Edge Gateways, often equipped with GPUs for rapid inference. The sensor end requires industrial-grade, ruggedized microphones designed to withstand harsh manufacturing environments.

Can this system integrate with our existing Manufacturing Execution System (MES)?

Yes. Integration is a standard part of our engineering process. We engineer the test station software to communicate directly with your MES or SCADA system via standard industrial protocols (e.g., OPC UA, MQTT, REST APIs) to automatically log pass/fail data, defect codes, and serial numbers for complete traceability.

Why use AI instead of traditional rule-based acoustic testing?

Traditional rule-based systems (e.g., “fail if volume exceeds X decibels at frequency Y”) are brittle. They struggle to distinguish between normal process variations and actual defects, leading to high false failure rates. AI-based systems learn the complex, non-linear “fingerprint” of a good vs. bad part, allowing them to detect subtle anomalies that rule-based systems miss while adapting to normal variations.

How does this system handle environmental variability?

We use a two-pronged engineering approach: physical microphone placement optimized for signal-to-noise ratio and DSP algorithms that filter out ambient industrial noise before the data reaches the AI model.

Is the AI "black box" or traceable?

Traceability is core to our integration. The system logs data directly to your Manufacturing Execution System (MES), providing a clear data trail for every serial number—essential for regulatory compliance and long-term quality analysis.